Roof Mounted Close Coupled Solar Water Heater

Advantages:

1). Highly efficient absorber of high performance with daily average efficiency over 50%;

2). Start up quickly, heat pipe transfer the heat energy into the storage tank in one direction.

3). Withstand pressure of 6 Bar, can be connected directly with city water.

4). No water inside the evacuated tubes; The solar water heater can still in service even with several tubes breakage;

5). Highly efficient insulation with polyurethane foam;

6). Simple structure, easy to assembly and install, diffuse flat plate reflector can be assembled easily with its module structure;

7). Can be used all year round in the cold climate;

8). Can be used together with Auxiliary electric boost;

9). Long service life, can be used as long as 15 years.

Model: STH-150L, STH-200L, STH-300L

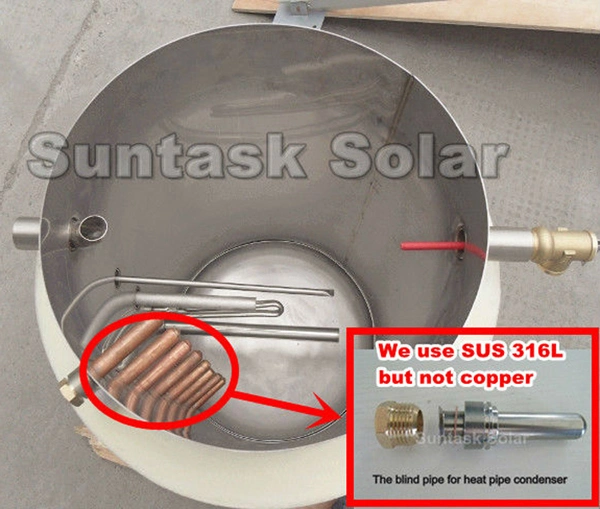

New Integrated Pressurized solar water heater: STH with 316L for blind tube

For our compact pressurized model STH we have special design: We use 316L material for blind tube instead of copper caecus tube, because for copper blind pipe after some period with the high temperature and high pressure, or in the water quality inferiority area, it will face corrosion and will happen blind pipe perforation phenomenon or blind pipe leakage. This new blind pipe is composed of 0.9 mm stainless steel 800 stamping with the red copper gasket.

New Design ADVANTAGES:

1. Slope roof and flat roof avaliable.

2. Looks more beautiful.

3. Inlet and Outlet hole at the back of the tank, any angel of roof is suitable.

4. Electric heater on the tank cover(side)

5. SUS316L stainless steel heat pipe condenser

Detailed data for Roof Mounted Close Coupled Solar Water Heater:

Storage Tank | |

| Inner Tank | SUS304-2B food grade stainless steel |

| Inner Tank Thickness | 1.5mm |

| Outer Tank | PVDF 0.4mm which is good at anti corrosion |

| Insulating Layer | Polyurethance Foam 50mm |

| Inlet/outlet | 3/4" |

| Vacuum Tube | |

| Material of the glass tube | Borosilicate glass |

| Absorptive Coating Grade | ALN/AIN-SS/CU |

| Length of Outer Tube | 1800mm |

| Length of Inner Tube | 1755mm |

| Outer Tube Diameter | 58mm |

| Inner Tube Diameter | 47mm |

| Glass Thickness | 1.6mm |

| Distance between two tubes | 75mm |

| Tube holder | UV stabilized nylon |

| Seals | Silicon seal |

| Thermal Expension | 3.3*10-6/º C |

| Absorption coefcient | 95± 1 % |

| Thermal emsision coefcient | 5 ± 1 % |

| Vacuum | P≤ 5.0*10-3 Pa |

| Stagnation Temperature | >200° C |

| Average heat loss | <0.8w/ m2. ° C |

| Maximum strength | 0.8Mpa |

| Resist hailstone | Φ 25mm |

| Resist wind | 30m/s |

| Heat Pipe | |

| Material | TU1 copper |

| Length | 1790mm |

| Condenser material | SUS316L |

| Diameter | Condenser dia. 14mm, body dia. 8mm |

| Contact sheets | Aluminum fin |

| Support Frame | |

| Material | Galvanized Steel |

| Thickness | 1.5mm |

| Angle | 25° |

| Others | |

| Working pressure | 6Bar |

| Daily efficiency | ≥ 55% (≥ 42% in winter) |

| Working temperature | 60° C ~ -35° C |

| Lifetime | 15 years |

| Optional | |

| Spare Tubes | We suggest you buy some tubes for backup |

| Controller | SR609 |

| Electric Heater | 1500W /2000W |