Overview:

The machine is specially used for filling strong corrosive liquids and liquids such as cosmetics that can't contact the metal. The parts of the machine that contact the liquids are all made of nonmetal anticorrosive materials. It is designed with submersible filling function, featured by accurate measurement and no bubble and drooping during the filing.The filling nozzle can lifting and dive .

Main technical parameters:

| Filling Head | 2 | 4 | 6 | 8 |

| Filling Volume | 100-1000ml | 100-1000ml | 100-1000ml | 100-1000ml |

| 1000-5000ml | 1000-5000ml | 1000-5000ml | 1000-5000ml | |

| Filling Type | Plunger Ration Filling | Plunger Ration Filling | Plunger Ration Filling | Plunger Ration Filling |

| Filling Speed | 300-600bph | 600-1500bph | 1500-2500bph | 3000-4000bph |

| Filling accuracy | ±1% | ±1% | ±1% | ±1% |

| Material | SUS304/316 | SUS304/316 | SUS304/316 | SUS304/316 |

| Air Pressure | 0.5-0.7Mpa | 0.5-0.7Mpa | 0.5-0.7Mpa | 0.5-0.7Mpa |

| Power | 220V,50Hz,500W | 220V,50Hz,500W | 220V,50Hz,500W | 220V,50Hz,500W |

| Air consumption | 200-300L/min | 200-300L/min | 200-300L/min | 200-300L/min |

| Weight | 400Kgs | 550Kg | 700Kgs | 900Kgs |

Appication:

Features:

1. This machine is designed for corrosive liquid (hydrochloric acid) and its unique designed filling structure can effectively prevent corrosion and leakage.

2.Precisely control filling amount with millisecond time

3.No bottle, no filling; no leakage, high precision

4. To ensure filling speed and avoid foam during filling process, the filling head has been designed to unique adjustabel form.

5.Adopt volumetric piston pump, pneumatic control ss check valve to filling various kinds of liquid from light to medium heavy.

6.Whole machine designed and manufactured accordance to GMP regulation.

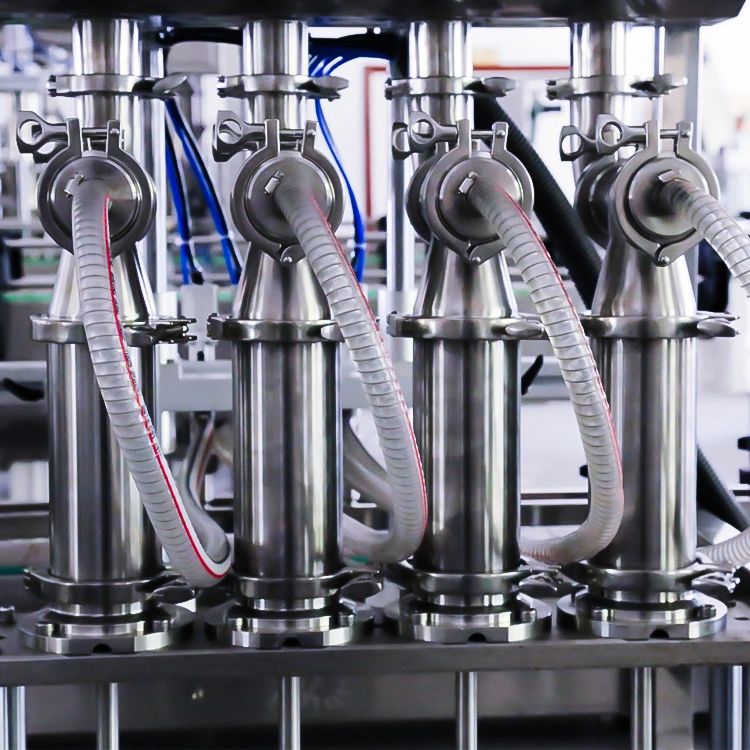

The details picture:

Add bottle fix device on the filling nozzle part, ensure when filling material, the bottle is fix in a right position, the filling nozzle use PP material customize, anti-corrosive and anti-drop. Length can customize according to different bottle.

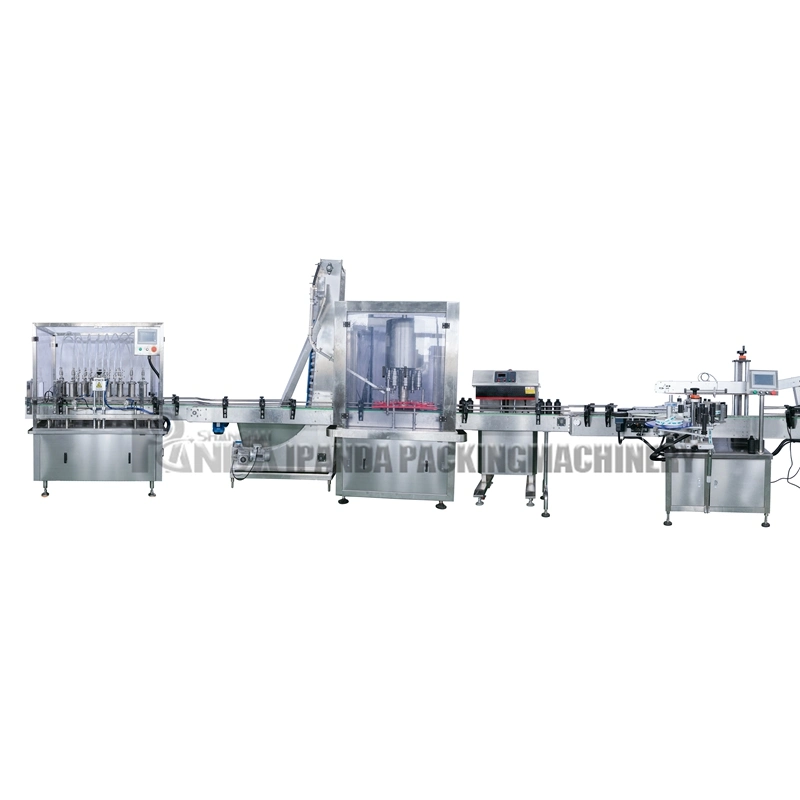

The whole machine line including :bottle feeding -Filling -Capping-Sealing -labeling -Collection

Machine all Electrical components can according to customer need to match, the PLC programe we espeically customize a set program for liquid accuracy filling , our plc will calculate the filling liquid and filling pulse automatically and show the filling volume and remain need filling volume in the touch screen, then if will begin second time filling automatically.

Company information

Shanghai iPanda Intelligent Machinery Co., Ltd. is committed to the equipment R&D, manufacture and trade of various types of packaging machinery. It is a high-tech enterprise integrating design, manufacture, trade , and R&D. The company's equipment R&D and manufacture team has more than 10 years of experience in the industry, accepting unique requirements from customers and providing various types of automatic or semi-automatic assembly lines for filling. Products are widely used in daily chemicals, medicine, petrochemical, foodstuff, beverage and other fields. Our products has a market in Europe, the United States and Southeast Asia, etc. won the new and old customers alike.

The talent team of Panda Intelligent Machinery gathers product experts, sales experts and after-sales service staffs, and upholds the business philosophy of "Good quality , Good service, Good prestige". We will continue to improve our own business level, expand our business scope, and strive to meet the needs of customers.

Our service:

1.We can supply OEC/ODM design.

2.We offer 1 year warranty and free spare parts supply(not man-made broken),we will also prepare enough spare parts delivered

together with the machines.

3.Our machine is designed in simple structure,so that easy for operation and

debugging.

4.Engineers available to service machinery overseas

5.Field installation, commissioning and training.Field maintenance and repair service

Transport

FAQ:

Q1: Are you factory or trading company?

A: We are factory.

Q2: Can you guarantee your quality?

A: Of course. We are the manufacture factory. More importantly, we put a high value on our reputation. Best quality is our principle all the time. You can be assured on our production completely.

Q3: What should I do if we are not able to operate the machine when we receive it?

A: Operation manual and video demonstration sent along with the machine to give instructions. Besides, we have professional after-sale group to customer 's site to solve any problems.

Q4: How could I get the spares on machines?

A:We will send extra sets of easy broken spares and accessories like O ring etc. Non-artificial damaged spares will be sent freely and shipping free during 1 year's warranty.